Automobile Industry Brilliance BMW

Automobile Industry Shanghai Volkswagen

Platform Type Enterprise – JD

Platform Type Enterprise -CAINIAO

Platform Type Enterprise – BICON

Platform Type Enterprise – SOLAR-SYSTEM

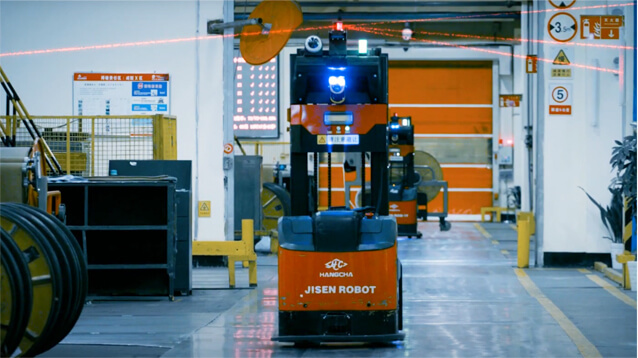

Tapping opportunities arising from the “Made in China 2025” strategy, in response to current industrial revolution – transformation to

innovation-driven & smart manufacturing, Hangcha seeks to provide high-end intelligent solutions to propel the transformation & upgrading

of the traditional manufacturing industries, and the integration of data-driven technologies within the industries.

Hangcha has 60 years of R&D experiences in traditional vehicle equipment and built up it’s production capacity. Hangcha has the support of

the high-end technology innovation systems consisting of the academician institutes, key enterprise institutes at provincial level

specializing in intelligent vehicle for industrial use, and post-doctoral programs etc.

By incorporating the cutting-edge AGV automation technologies from Kollmorgen ( NDC8 system), developing and innovating twice on this

basis, Hangcha strives to become world leading provider of turn-key solutions in intelligent logistics encompassing the planning & design of

logistics, systems integration, vehicle manufacturing, marketing & engineering services, to deliver internationally competitive products &

solutions based on smart logistics driven technologies in the market.

Hangcha Group worked with BMW Brilliance to deploy Hangcha’s first AGV system at BMW Brilliance’s automotive manufacturing facility.

CHAOYANG Tire successfully integrated Hangcha Group’s AGV based intelligent logistic system into their manufacturing facility. They were able to use 11 AGV’s to replace 20 manned pieces of material handling equipment and increase their productivity.

Ningbo Blue Dragon Logistics, an oceanic shipping warehouse service, uses Automated Guide Reach Trucks and Stackers to automate their warehouse and increase productivity.

Seraphim Solar System partnered with Hagcha Group and Kollmorgen to make their warehouse fully automated. They used Hangcha Group’s Narrow Aisle High Reach AGV’s to increase their production to 24 hours a day. This lead to a 20% increase in their productivity.

Here you can send us an inquiry concerning general questions about Hangcha.

The form was submitted successfully.

You have applied successfully!